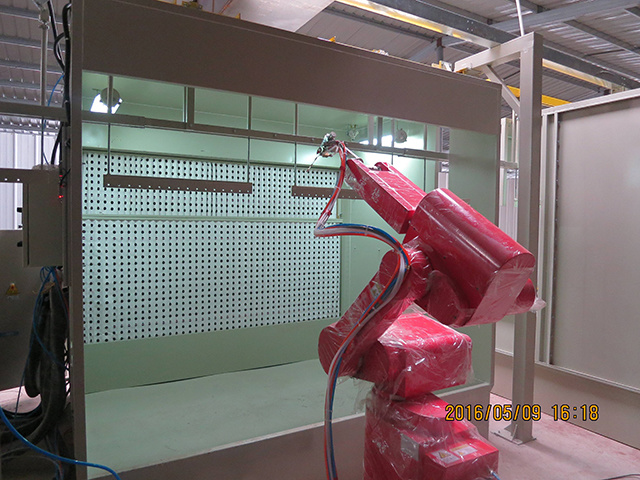

Computer Case Automatic Painting Robot Spray Painting Machine Line Spray painting Robotic Arm

隐藏域元素占位

- Product Description

-

Video Description

The Explosion-proof Computer Case Automatic Painting Robot is an efficient spraying equipment that integrates automation and intelligence and is designed for surface spraying of computer cases. It uses advanced robotics technology and precise spraying control systems to achieve high-quality and efficient spraying operations. Compared with traditional manual spraying, automatic spraying robots have higher production efficiency, more uniform spraying effects,and less manual intervention, and are widely used in the computer hardware production industry.

Product Parameters

Application Plastics, Hardware, Wood products, Glass, Ceramics, Magnets and other products Spraying process Spray painting Spraying method Robot Drying method Tunnel furnace Model RDPT010203-1300

RDPT010203-2000

RDPT010203-2700

Axes 6-axis

6-axis

6-axis

Reach 1300mm

2000mm

2700mm

Wrist type Connecting wrist

Hollow wrist

Hollow wrist

Payload at wrist 10kg

10kg

10kg

Maximum liner compensation speed 2.0m/s

2.0m/s

2.0m/s

Repetitive positioning accuracy ±0.2mm

±0.5mm

±0.5mm

Motion range JT1 Rotation ±170°

±145°

±145°

JT2 Lower Arm +135° to -90°

+105° to -55°

+115° to -65°

JT3 Upper Arm +168° to -80°

+90° to -80°

+90° to -80°

JT4 Rotation 1 ±360°

±720°

±720°

JT5 Wrist Pitch ±120°

±720°

±720°

JT6 Rotation 2 ±720°

±410°

±410°

Weight

190kg

460kg

600kg

Product Structures

1. Robot arm system: The robot arm is the core part of the equipment, usually with a multi-joint robot arm design, with extremely high flexibility and precision. It can automatically adjust the angle according to the shape and size of different chassis to achieve all-round spraying. The robot arm moves smoothly, which can avoid unevenness or omissions during the spraying process.

2. Spraying system: The spraying system consists of a high-pressure spray gun and a spraying control system. The spray gun can adjust the amount of spraying and the uniformity of the coating as needed while controlling the speed and direction of the spraying to ensure that each chassis surface is evenly coated. The spraying system is also equipped with an air filter to prevent external impurities from affecting the spraying quality.

3. Transmission system: The Automatic Painting Robot is equipped with an automated transmission system, which delivers the computer case to the spraying area through a mechanical conveyor belt or clamping device to ensure a smooth spraying process. The transmission system can be intelligently adjusted according to the production rhythm to improve overall work efficiency.

4. Control system: The sophisticated control system can be operated through a touch screen interface to set spraying parameters and monitor in real-time. The system also supports automatic diagnosis and troubleshooting, which greatly reduces manual intervention and improves the automation level of the production line.

5. Cleaning and maintenance system: The automatic painting robot is equipped with an intelligent cleaning and maintenance system. After completing the spraying work, it automatically cleans the spray gun and related components to prevent residues from affecting the spraying effect. The cleaning system has a high degree of automation, which ensures the stability and efficiency of the equipment in long-term use, reduces the workload of manual cleaning, and improves the overall production efficiency and product quality.

Explosion proof Automatic Painting Robot brings a more stable production process and higher painting quality through refined structural design and efficient automation technology. It is an indispensable intelligent device in the manufacture of modern electronic products.

Key words:

Hardware

NdFeB surface treatment

Electrostatic painting machine

Solder mask ink spray production line

Robotic arm for painting

Paint robotic arm

Automated spray paint machine

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language