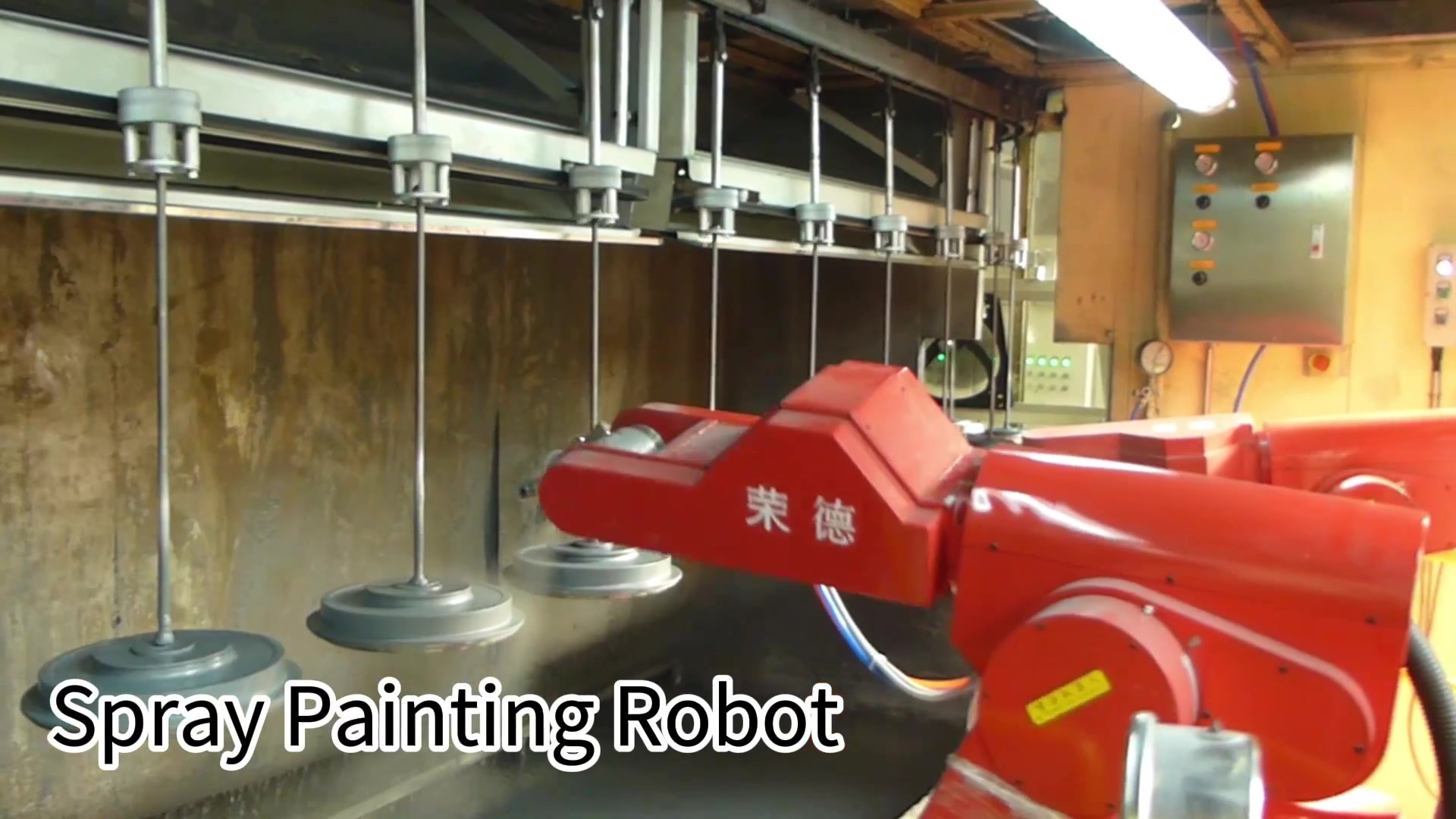

Auto Parts Spray Painting Line

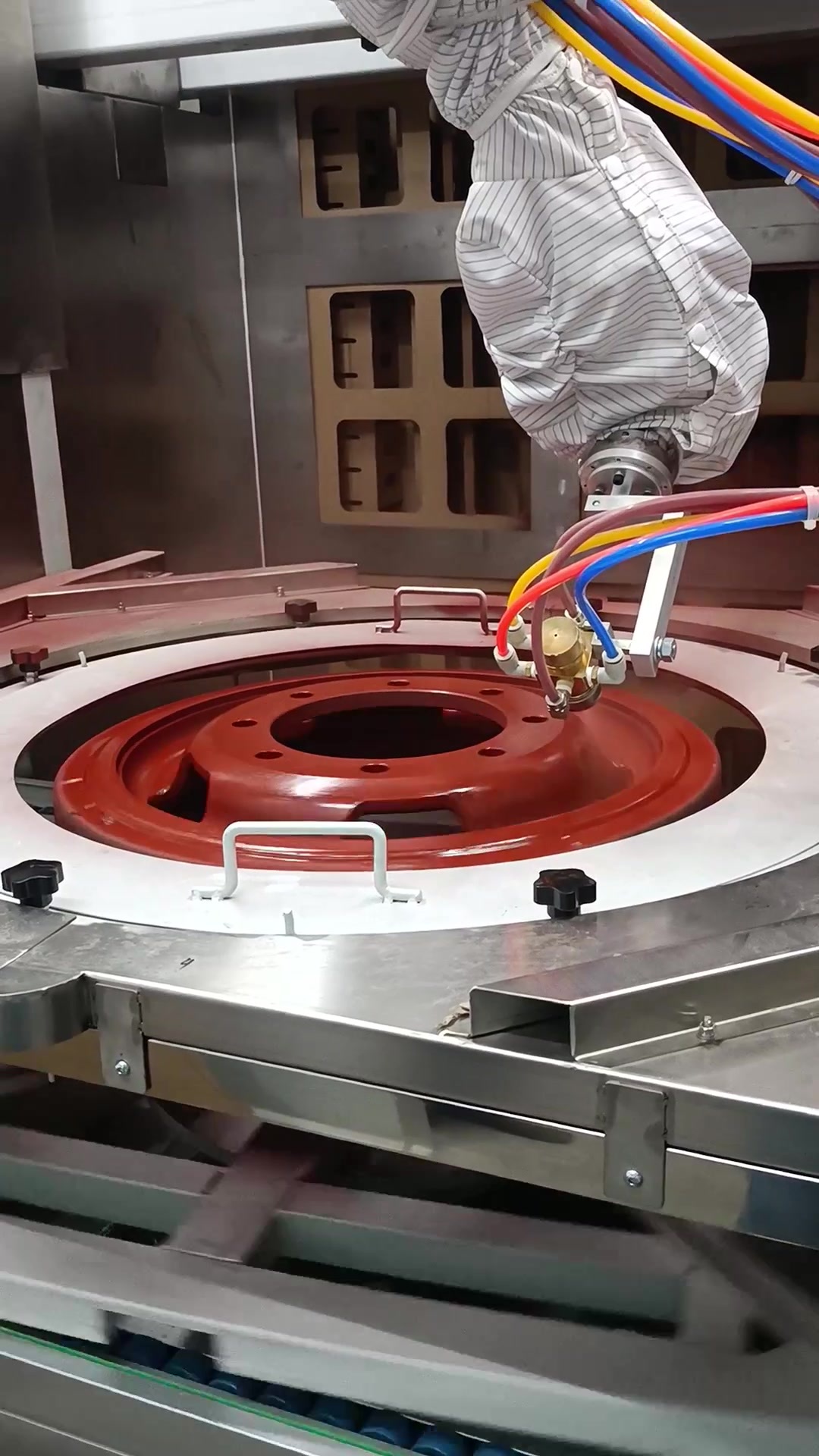

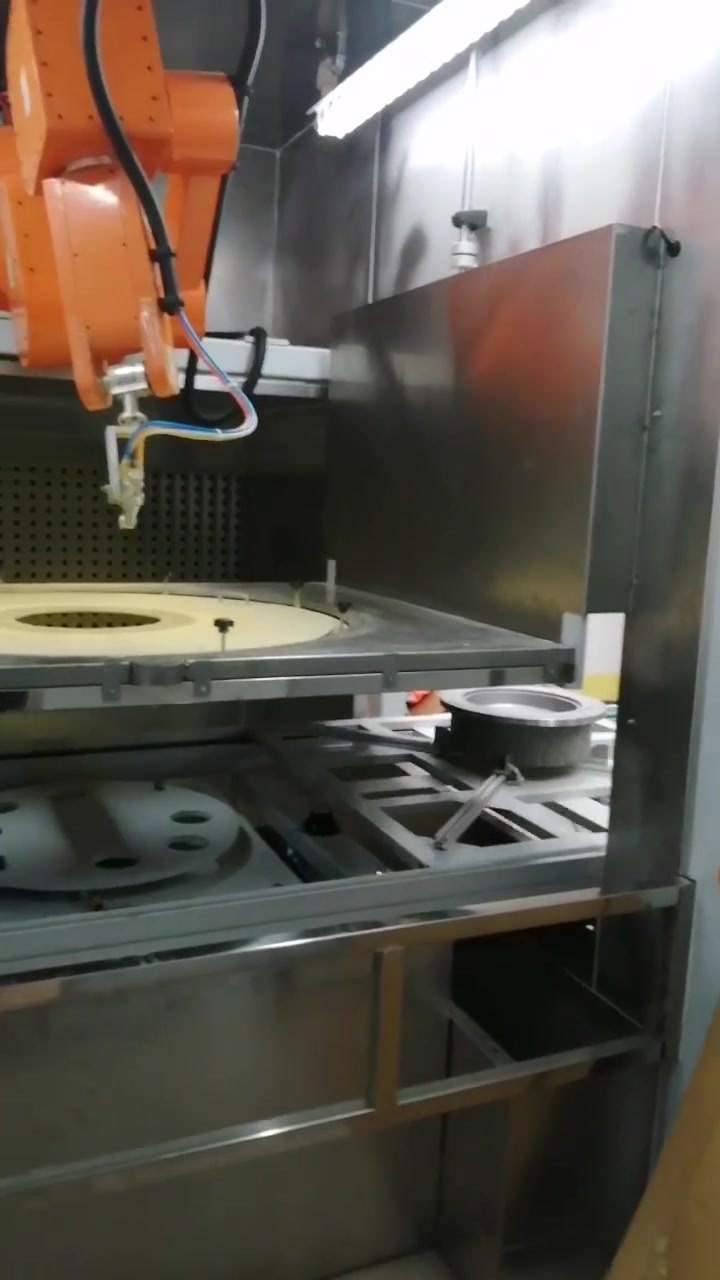

The automotive industry, with its high production capacity, fast pace, and high surface requirements for painting, has become the most widely used industry for spraying robots. It is often used for painting internal and external decorative components such as brake discs, tail wings, navigation instrument panels, door handles, and headlights.

Usage scenario:

Brake Disc

Car Bumper

Tail Wing

Automotive parts spraying robot system

01

Using robot spraying, the spray coating is uniform, the speed is stable, the glossiness is good, and the product qualification rate is high;

Built in oil saving program, efficient and paint saving, saving 30% of paint;

02

It can work 24 hours without interruption, with high reliability and increased production capacity;

03

Automatically adjust the height, front and back, angle, and position of the spray gun according to the changes in the sprayed product, and flexibly control the amount of spray oil;

04

Spraying robots are environmentally friendly, have high safety performance, and are easy to operate and learn;

05

The spray painting robot has a long lifespan, no vulnerable parts, simple maintenance, and fewer vulnerable parts such as guide rails and belts compared to the five axis spray painting platform;

06

The program can store 3000 sets and can be copied on a USB drive, making management convenient and simple;

07

Widely applicable, suitable for various irregular workpieces, with high usage rate, can dynamically synchronize tracking of conveyor belts, and cooperate with production line spraying;

Video display

Related products