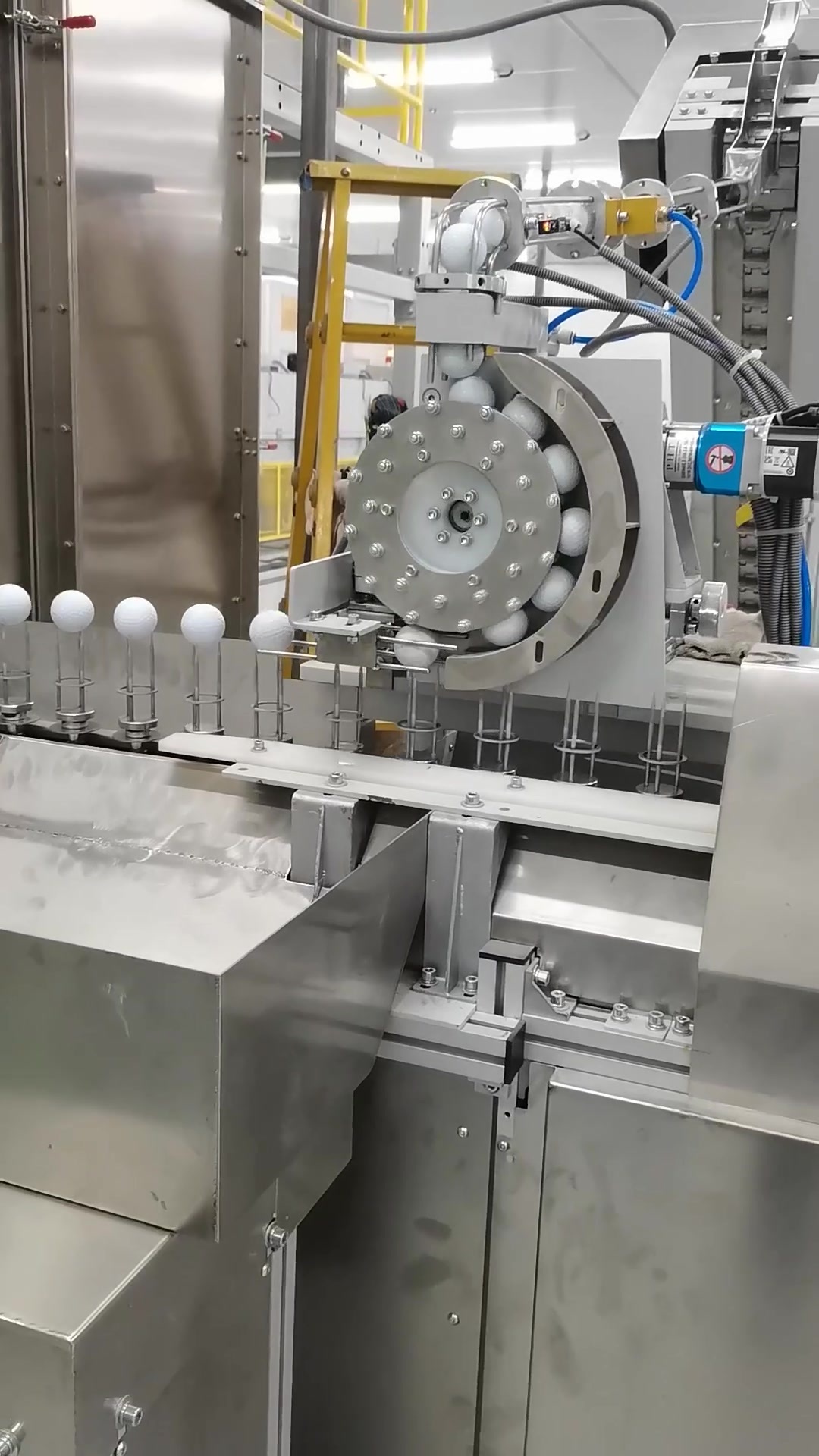

Golf Ball Spray Painting Line

In the field of golf ball production, it is necessary to spray paint the surface of the produced golf balls to improve their aesthetics, wear resistance, and corrosion resistance. Paint is usually sprayed onto the surface of the product in a mist form through a nozzle. Rongde spraying equipment is a comprehensive golf ball production equipment that sprays paint evenly and stably, saves energy, increases output, and reduces costs.

RDROBOT Golf Ball Spraying Production Line is applied to the surface painting treatment of high-end golf ball cores, game balls, PU game balls, float balls, gift balls, fluorescent balls, various colored balls, and golf sports balls. The spraying engineering process mainly includes spraying primer, topcoat, drying, printing, and other processes.

Starting from feeding, automatic conveying, automatic ball loading, automatic dust removal, automatic spraying, mechanical arm automatic rotation, automatic cleaning of spray painting fixtures, automatic drying, automatic cooling, automatic unloading, automatic counting, and receiving. The entire line has achieved automation, unmanned operation, and high production efficiency. The golf ball transfer robot adopts high-precision synchronous grasping motion, and the paint spraying line operates continuously. Compared with intermittent start stop motion, the production efficiency is higher and the quality is more stable.

Composition structure:

Air Supply Unit

Automatic Drying T-line

Robot Arm Rotating Cleaning Brush

Video Display

Related Products