Golf Ball Manufacturing Method Golf Ball Surface Finishing Painting System Production Line

隐藏域元素占位

- Product Description

-

Video Description

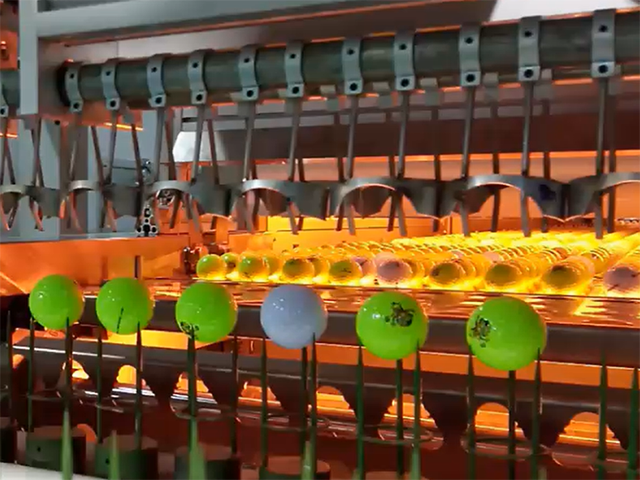

In golf ball manufacturing, achieving a flawless surface is vital for aesthetics, durability, and corrosion resistance. Rongde spraying equipment-golf ball coating robot efficiently applies paint with consistent and uniform coverage, saving energy and costs while increasing output.

Our company's golf ball spraying production line caters to a diverse range of golf balls, including high-end cores, competition balls, PU competition balls, floating balls, gift balls, fluorescent balls, various colored balls, and sports balls. The spraying process includes priming, topcoat application, drying, printing, and other finishing steps to achieve the desired results.

Product Parameters

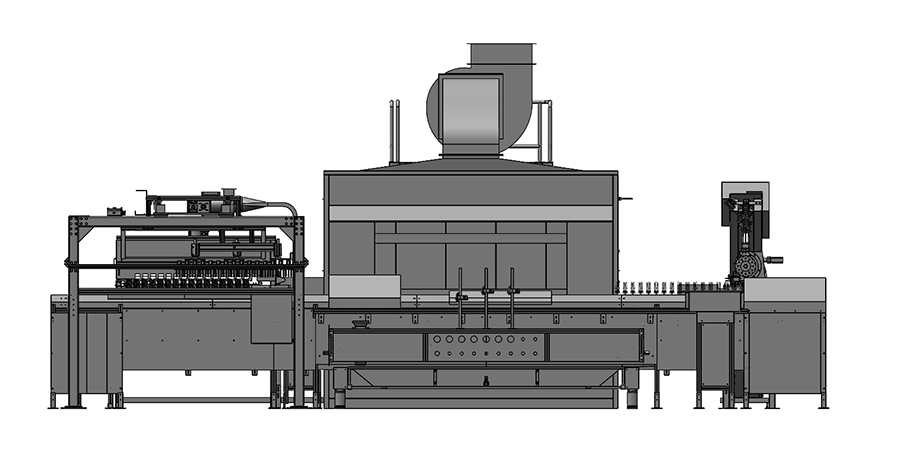

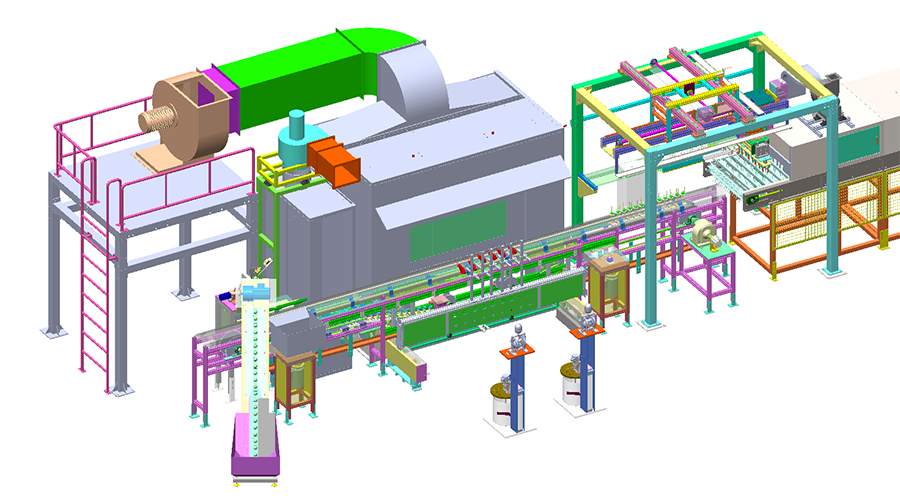

Application Golf core, Competition ball, PU competition ball, Floating ball, Gift ball, Fluorescent ball Spraying process Spray painting Spraying method Reciprocator Drying method Tunnel furnace

Product Features

From feeding to automatic conveying, ball loading, dust removal, spraying, robot transfer, fixture cleaning, drying, cooling, unloading, counting, and collection, our entire production line is fully automated and unmanned, ensuring exceptional production efficiency.

Our golf ball transfer manipulator utilizes high-precision motion to synchronously grasp balls, enabling continuous operation of the painting line. This seamless workflow results in higher production efficiency and enhanced quality stability compared to start-stop movements with gaps.

Key words:

Golf

Golf ball coating equipment

NdFeB powder spray

NdFeB surface treatment

Golf ball spraying

Golf ball coating robot

Pcb ink spray production line

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language