Magnet Coating Line

High speed spraying of neodymium iron boron magnetic materials

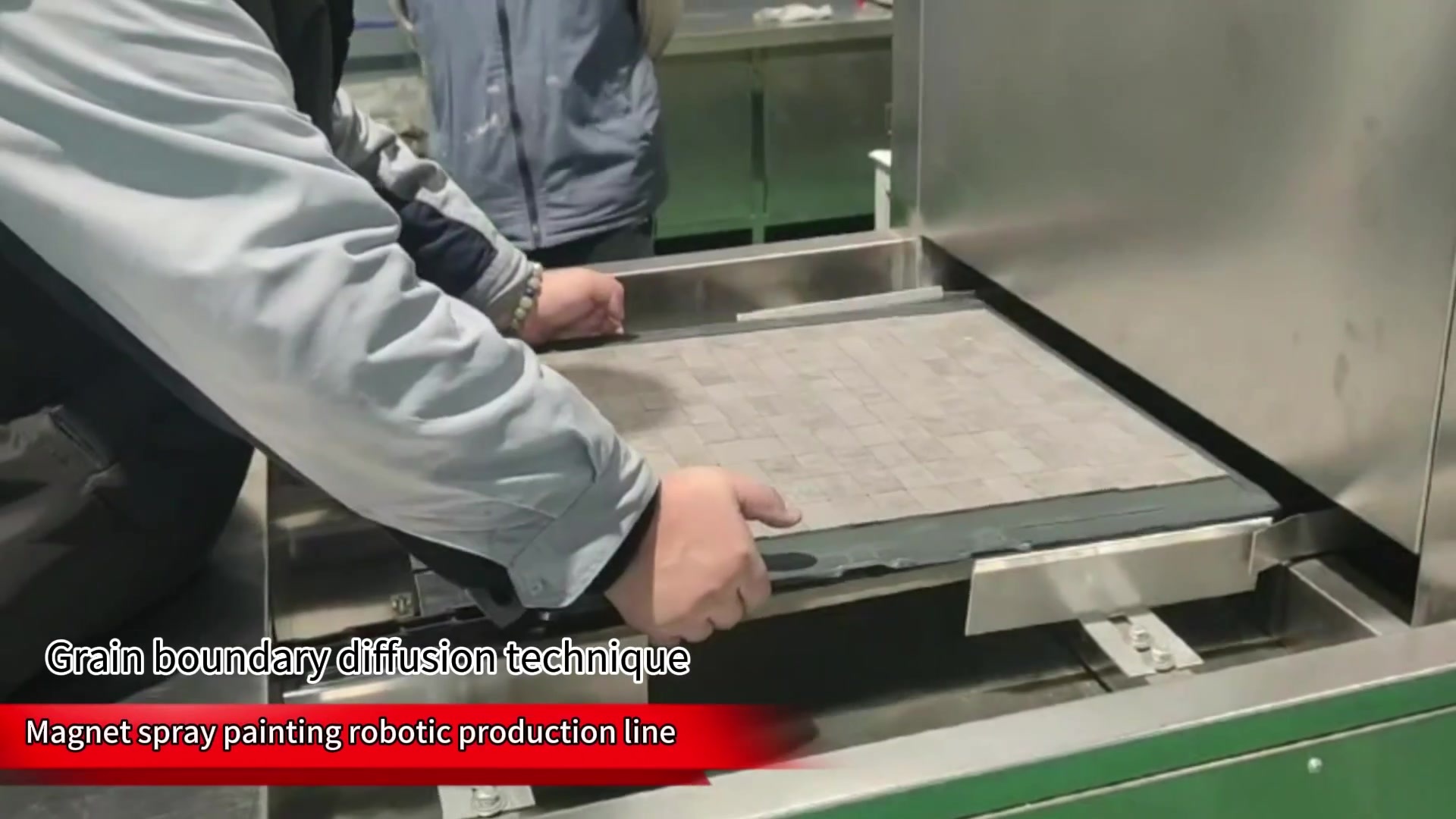

RdRobot has advanced high-speed epoxy and diffusion coating technology for magnetic materials, specializing in the production of neodymium iron boron grain boundary diffusion equipment, magnetic material epoxy spraying lines, and ferrite electrostatic powder spraying equipment. It adopts high-precision spraying, with uniform film thickness, high yield, and PCT salt spray testing meeting standards. It has good anti-corrosion performance and improves the coercivity of magnetic materials.

01

Neodymium iron boron diffusion / permeation spraying system

Application Scope

Mainly used for surface infiltration operations of high-performance sintered neodymium iron boron rare earth permanent magnet materials, the product coating has good uniformity and a weight increase of 0.5% to 1%.

Process Flow

Upper part → preheating → automatic spraying of side A → drying → cooling → automatic flipping → preheating → automatic spraying of side B → drying → cooling → lower part

Upper part → preheating → automatic spraying of side A → drying → cooling → automatic flipping → preheating → automatic spraying of side B → drying → cooling → lower part

Technical Features

High paint utilization rate

Adopting multi-layer filtration, the filtration accuracy is high, and the comprehensive recovery rate of the coating can reach 98%.

Stable quality

The atomization, spraying amplitude, and oil quantity of the spray gun can be precisely sprayed through PLC remote control, resulting in good product uniformity.

Easy to maintain

The oil circuit adopts anti sedimentation technology to reduce the risk of paint blockage.

Safe and explosion-proof

The servo motor of the spray room adopts positive pressure inflation explosion-proof measures.

02

Neodymium iron boron epoxy automatic spraying equipment

Application Scope

Suitable for products with high requirements for coating environment, it can reduce the impact of external dust or temperature and humidity on product quality through high standard environments such as dust-free spraying workshops, constant temperature and humidity, etc.

Process Flow

Upper part → Automatic dust removal → Preheating → Automatic spraying of surface A → Surface drying → Drying → Cooling → Semi automatic flipping → Automatic dust removal → Preheating → Automatic spraying of surface B → Surface drying → Drying → Cooling → Lower part

Upper part → Automatic dust removal → Preheating → Automatic spraying of surface A → Surface drying → Drying → Cooling →

Semi automatic flipping → Automatic dust removal → Preheating → Automatic spraying of surface B → Surface drying → Drying → Cooling → Lower part

Technical Features

Energy conservation

The modular design of the spraying equipment adopts multiple sets of highly reliable pneumatic doors to divide the equipment into spraying area, preheating area, surface drying area, and drying area, reducing heat loss during 24-hour continuous production.

Digitization

Adopting a stable paint supply system, high-precision digital settings for spray gun oil quantity, atomization, and fan-shaped.

High-precision

The spraying robotic arm with high repeatability and precision can control the tolerance of coating thickness within ± 5um, ensuring stable quality and greatly improving product qualification rate

Consistent quality

Adopting a specially designed furnace air transportation system, the temperature difference inside the furnace can be controlled within ± 5 ° C, resulting in high product quality consistency

03

Soft magnetic electrostatic powder spraying production line

Application Scope

Suitable for soft magnetic products.

Process Flow

Upper part → preheating → automatic spraying of side A → drying → cooling → semi-automatic flipping → preheating → automatic spraying of side B → drying → cooling → lower part

Upper part → preheating → automatic spraying of side A → drying → cooling → semi-automatic flipping → preheating →

automatic spraying of side B → drying → cooling → lower part

Technical Characteristics

Automation

Integrated production line for preheating, powder spraying, and drying.

Precise and controllable

The use of touch screen digital control makes the spraying process more stable, precise, and easy to operate. Spray parameters can be backed up and output can be calculated.

Powder spray gun and powder supply system

Adopting an intelligent automatic powder spray gun, it has a small volume, convenient debugging operation, high powder loading rate, uniform and stable powder output, smooth and even spraying surface, strong penetration, and safe use.

Efficiency improvement

The return line eliminates manual transmission; Adopting a semi-automatic flipping machine to reduce labor intensity.

04

Automatic painting table for magnetic materials

Application Scope

Suitable for small batch production and can also be used as a spray coating laboratory. Widely used, with strong applicability, professional spraying with strong targeting, and high output to achieve high-quality and high-efficiency spraying.

Process Flow

Loading → Rotating into the spraying area → Spray gun on oil → Cooperating with X1, Y2, Z3, W4, R5 axis movement, spray A surface first → Rotate 90 degrees → Spray B surface → Rotate 90 degrees → Spray C surface → Rotate 90 degrees → Spray D surface → Rotate out → Rotate in → Cycle

Loading → Rotating into the spraying area → Spray gun on oil → Cooperating with X1, Y2, Z3, W4, R5 axis movement, spray A surface first → Rotate 90 degrees → Spray B surface → Rotate 90 degrees → Spray C surface → Rotate 90 degrees → Spray D surface → Rotate out → Rotate in → Cycle

Technical Characteristics

Flexibility

Suitable for various shapes of magnetic materials such as flat, tile, circular, and cylindrical.

Low pollution

Combined with a water curtain cabinet, it can effectively absorb excess paint mist and purify the air quality in the workshop.

Easy to clean

The rotary table adopts a 180 degree indexing control, and the material tray is completely immersed in the water tank, resulting in less pollution.

Fast return on investment

Can work continuously 24 hours a day, and recover investment for about a year.

Video Display

Related Products