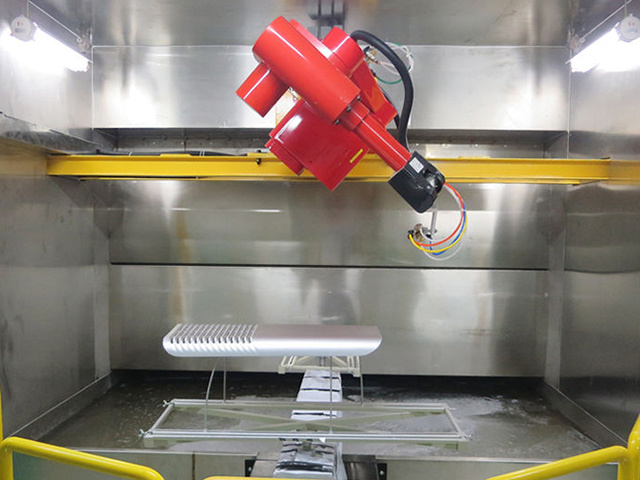

Automated Robotic Plastic Part Painting System Painting Machine Robot

隐藏域元素占位

- Product Description

-

Video Description

The high yield plastic coating machine is a kind of equipment specially used for coating plastic materials on the surface of various substrates. Its main function is to evenly attach the plastic coating to the surface of the product by heating, spraying, or soaking to improve corrosion resistance, wear resistance, and beautiful appearance.

It adopts the latest spraying technology and can adapt to various substrates to ensure the best coating quality and adhesion. The equipment is equipped with an intelligent control system, and users can easily set the coating thickness, temperature, and curing time. The operation is simple and safe.

The high-yield plastic coating machine has excellent corrosion resistance and wear resistance. Whether in large-scale production or small-batch customization, it can provide stable performance and an excellent coating effect. By choosing this coating machine, you will get a technologically advanced and reliable quality solution to add higher value to your products.

Product Parameters

Application Plastics, Hardware, Wood products , Glass, Ceramics, Magnets and other products Spraying process Spray painting Spraying method Robot Drying method Tunnel furnace Model RDPT010203-1300

RDPT010203-2000

RDPT010203-2700

Axes 6-axis

6-axis

6-axis

Reach 1300mm

2000mm

2700mm

Wrist type Connecting wrist

Hollow wrist

Hollow wrist

Payload at wrist 10kg

10kg

10kg

Maximum liner compensation speed 2.0m/s

2.0m/s

2.0m/s

Repetitive positioning accuracy ±0.2mm

±0.5mm

±0.5mm

Motion range JT1 Rotation ±170°

±145°

±145°

JT2 Lower Arm +135° to -90°

+105° to -55°

+115° to -65°

JT3 Upper Arm +168° to -80°

+90° to -80°

+90° to -80°

JT4 Rotation 1 ±360°

±720°

±720°

JT5 Wrist Pitch ±120°

±720°

±720°

JT6 Rotation 2 ±720°

±410°

±410°

Weight

190kg

460kg

600kg

Product Structures

The basic structure of the plastic coating equipment usually includes a feeding system, a heating device, a spraying system, a coating curing system and a control system.

1. Feeding system: Responsible for evenly feeding the plastic raw materials into the spraying or soaking area to ensure the continuous supply of materials.

2. Heating device: Heats the plastic to a suitable temperature to facilitate subsequent spraying or coating and improve the quality of the coating.

3. Spraying system: Uses nozzle technology to atomize the heated plastic to ensure that the coating is evenly covered on the surface of the substrate.

4. Coating curing system: Quickly cures the coating through hot air or ultraviolet rays to ensure the adhesion and durability of the coating.

5. Control system: Integrated intelligent control panel allows users to set and adjust coating parameters such as thickness, temperature, and curing time for precise operation.

6. Exhaust system: Effectively exhausts the exhaust gas generated during the spraying process of high yield plastic coating machine to ensure the safety and cleanliness of the working environment.

Key words:

Plastics

Robotic arm for painting

Automatic spraying robot

Golf ball coating equipment

NdFeB powder spray

Electrostatic painting machine

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language