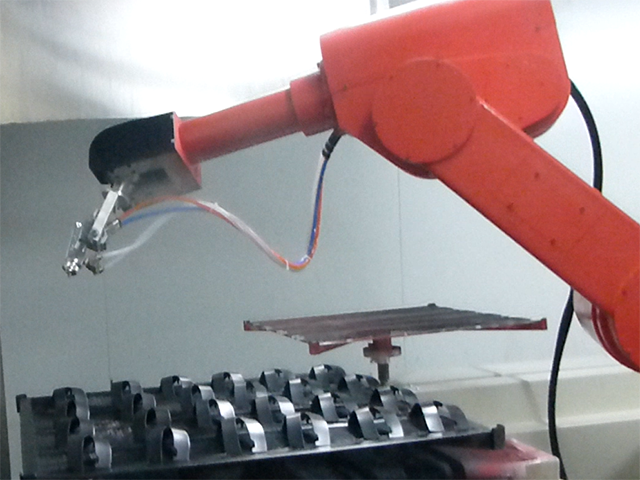

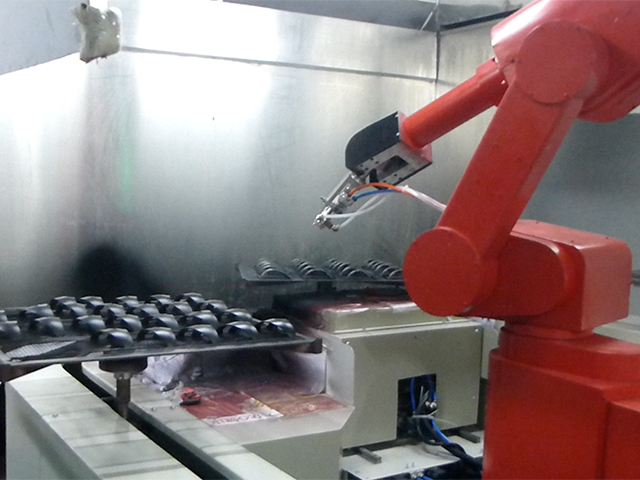

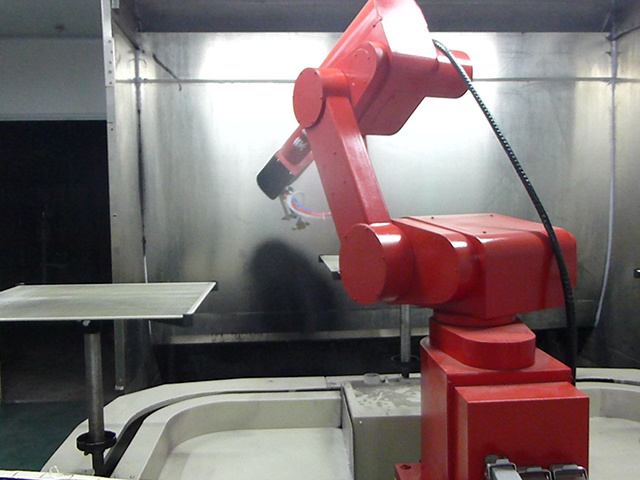

Automated Spray Painting Equipment for Mouse Cases Spraying Robot for Floor-Rail Production Line

隐藏域元素占位

- Product Description

-

Video Description

This explosion-proof paint spray robot is specially designed for mouse shell and floor rail production lines. It has efficient and accurate spraying capabilities and can meet the dual needs of modern production for quality and efficiency. Using advanced spraying technology, the robot can ensure that the surface coating of each product is uniform, smooth, and flawless, greatly improving the appearance quality and market competitiveness of the product.In addition, the robot is equipped with an intelligent control system that supports multiple spraying modes, which is convenient and quick to switch and adapt to the spraying of products of different specifications and materials. Its modular design makes maintenance and upgrading more convenient, while reducing the failure rate and maintenance cost of the equipment.

Product Parameters

Application Plastics, Hardware, Wood products, Glass, Ceramics, Magnets and other products Spraying process Spray painting Spraying method Robot Drying method Tunnel furnace Model RDPT010203-1300

RDPT010203-2000

RDPT010203-2700

Axes 6-axis

6-axis

6-axis

Reach 1300mm

2000mm

2700mm

Wrist type Connecting wrist

Hollow wrist

Hollow wrist

Payload at wrist 10kg

10kg

10kg

Maximum liner compensation speed 2.0m/s

2.0m/s

2.0m/s

Repetitive positioning accuracy ±0.2mm

±0.5mm

±0.5mm

Motion range JT1 Rotation ±170°

±145°

±145°

JT2 Lower Arm +135° to -90°

+105° to -55°

+115° to -65°

JT3 Upper Arm +168° to -80°

+90° to -80°

+90° to -80°

JT4 Rotation 1 ±360°

±720°

±720°

JT5 Wrist Pitch ±120°

±720°

±720°

JT6 Rotation 2 ±720°

±410°

±410°

Weight

190kg

460kg

600kg

Product Features

1. Precise control: Using an advanced control system to achieve high-precision spraying and ensure uniform coating.

2. Multi-mode adaptation: Supporting multiple spraying modes to meet the needs of different products and materials.

3. Intelligent design: With intelligent control function, convenient operation and monitoring, and improved user experience.

4. Labor saving: Reducing labor costs and improving the automation level of production lines.

5. Modular structure: Easy to maintain and upgrade, reducing equipment failure rate.

6. Strong stability: Stable design, suitable for long-term high-load work.

7.High safety performance: Equipped with safety protection measures to ensure the safety of operators.

8. Flexible configuration: It can be flexibly configured according to production needs to meet personalized needs.

With its excellent performance and flexible application, the paint spray robot is an ideal choice for realizing production automation and improving overall benefits, helping people gain competitive advantages in a fierce market environment

Key words:

Plastics

Automated spray paint machine

Pcb solder mask ink spraying line

PCB spraying machine

NdFeB powder spray

Explosion proof spraying robot

Pcb ink spraying machine

Pcb automatic spraying production line

Pcb ink spray production line

NdFeB spray paint

NdFeB epoxy paint spraying line

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language