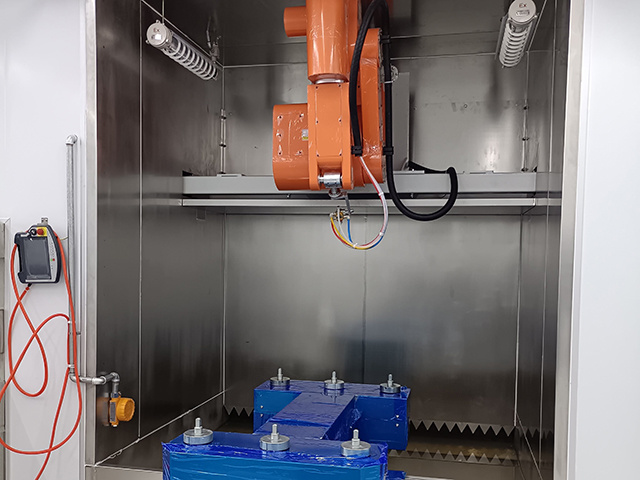

Robot Spray Painting on a iPad Design Manufacturing of Robotic Arm for Spray

隐藏域元素占位

- Product Description

-

Video Description

The environmental robotic arm for painting has become a key equipment for improving efficiency and quality in modern painting production due to its high degree of automation, precise coating control, efficient production, reduction of paint waste, and ability to adapt to complex workpiece shapes.

Product Parameters

Application Plastics, Hardware, Wood products, Glass, Ceramics, Magnets and other products Spraying process Spray painting Spraying method Robot Drying method Tunnel furnace Model RDPT010203-1300

RDPT010203-2000

RDPT010203-2700

Axes 6-axis

6-axis

6-axis

Reach 1300mm

2000mm

2700mm

Wrist type Connecting wrist

Hollow wrist

Hollow wrist

Payload at wrist 10kg

10kg

10kg

Maximum liner compensation speed 2.0m/s

2.0m/s

2.0m/s

Repetitive positioning accuracy ±0.2mm

±0.5mm

±0.5mm

Motion range JT1 Rotation ±170°

±145°

±145°

JT2 Lower Arm +135° to -90°

+105° to -55°

+115° to -65°

JT3 Upper Arm +168° to -80°

+90° to -80°

+90° to -80°

JT4 Rotation 1 ±360°

±720°

±720°

JT5 Wrist Pitch ±120°

±720°

±720°

JT6 Rotation 2 ±720°

±410°

±410°

Weight

190kg

460kg

600kg

Product Unique Features and Benefits

1. Highly automated: One of the biggest advantages of the environmental robotic arm for painting is its highly automated function. Through preset programs and intelligent control systems, the robot can automatically complete the spraying task, greatly reducing human intervention. This not only improves production efficiency but also ensures the consistency and stability of the coating process.

2. Precisely control coating quality: The robotic spray arm can accurately control the spraying angle, nozzle distance, and paint flow, thereby ensuring that the coating thickness of each workpiece is uniform and flawless. For products that require high-quality coating, such as automotive parts, home appliance housings, etc., the accuracy of the robotic spray arm is particularly important.

3. Improve production efficiency: The environmental robotic spray arm can run continuously for a long time without rest, which significantly improves the overall efficiency of the production line. The robot can quickly complete repetitive spraying tasks, greatly shortening the production cycle and increasing output.

4. Reduce paint waste: The robotic spray arm uses advanced spraying technology, such as electrostatic spraying, so that the paint can be accurately attached to the target surface, avoiding paint splashing and waste. This not only reduces the cost of paint but also improves the environmental friendliness of coating.

5. Adapt to complex workpiece shapes: The robot spray arm is highly flexible and can adapt to workpieces of different shapes and sizes. Whether it is large-area flat spraying or complex-shaped workpieces, the robot can complete efficient spraying by adjusting the spraying angle and position.

The environmental robotic arm for painting is widely used in the field of industrial coating due to its high efficiency, precision, and energy saving. It is an indispensable and important equipment in modern coating production.

Key words:

Plastics

Solder mask ink spray production line

Automatic painting robot

Robotic arm for painting

Paint robotic arm

Automated spray paint machine

Pcb coating equipment

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language