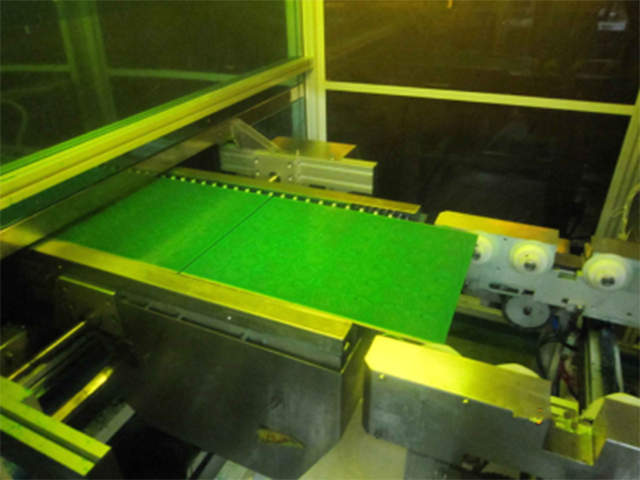

PCB Auto Low-Pressure Spray Coating Machine Ink Automatic Coating Equipment

隐藏域元素占位

- Product Description

-

Video Description

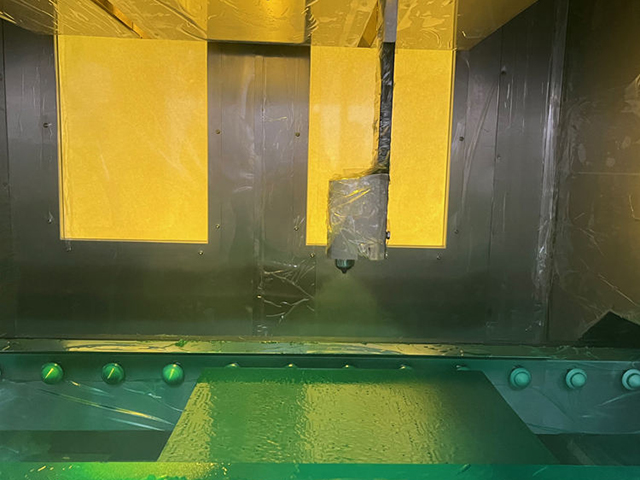

Compared to low-pressure spraying technology, our company's new high-speed spraying equipment adopts advanced technologies such as precise adjustable spacing technology, high viscosity technology, high-speed robotic arm, and dry filtration. This reduces ink overspray and air spray, increasing production by 30% compared to low-pressure spraying. Additionally, it has no wastewater discharge and does not require frequent replacement of filter cotton. It is suitable for high viscosity inks, reducing ink diluent usage, and decreasing VOC emissions by 20%, thereby reducing pollutants from the source and making it more environmentally friendly.

Product Parameters

Application PCB Spraying process Solder mask ink coating Spraying method Reciprocator, Robot Drying method Tunnel furnace Technical Parameters

Project High viscosity high speed robot spraying line Anti-blocking high-apeed robot spraying line Low pressure spraying line Model PCBHS-X3 PCBHS-X2 PCBHS-X1 Dimensions L8800*W1950*H2565mm L8800*W1950*H2565mm L8300*W1950*H2200mm Maximum spray plate size L730*W630mm L730*W630mm L730*W630mm Minimum spray plate size L300*W300mm L300*W300mm L300*W300mm Spray plate thickness T0.8~6.0mm,no deformation T0.8~6.0mm,no deformation T0.8~6.0mm,no deformation Copper thickness <3oz(finished copper thickness)spray noce to complete <2oz(finished copper thickness)spray noce to complete <2oz(finished copper thickness)spray noce to complete Anti-blocking rate Finished product hole diameter ≥0.25mm without clogging Finished product hole diameter ≥0.25mm without clogging Finished product hole diameter ≥0.25mm without clogging ink viscosity High viscosity 100S,low viscosity 30S Low viscosity 30S Low viscosity 30S Coating quality Line surface≥10um,line angle≥5um Line surface≥10um,line angle≥5um Line surface≥10um,line angle≥5um Film thickness uniformity ≥90% ≥90% ≥90% Spray gun travel speed 1.5~2.4M/S 1.5~2.4M/S 1.0~1.5M/S Maximum spray gun travel acceleration 50M/s² 50M/s² 50M/s² Overspray distance 50mm 50mm 100mm Board spacing 10mm 10mm 40mm Line conveying speed 3.0~4.5m/min adjustable 2~3m/min adjustable 2~3m/min adjustable Monthly output(calculated based on board size 500*500mm) 50000m²(4M/min) 35000m²(2.8M/min) 35000m²(2.8M/min) Installed power AC380,three-phase five-wire system 50Hz,6KW AC380,three-phase five-wire system 50Hz,6KW AC380,three-phase five-wire system 50Hz,5KW Working pressure Air flow rate:2m3/min Pressure:7kgf/cm3 Air flow rate:2m3/min Pressure:7kgf/cm3 Air flow rate:2m3/min Pressure:7kgf/cm3 Ventilation requirements 7500m³/h,resdual pressure 800Pa 7500m³/h,resdual pressure 800Pa 7500m³/h,resdual pressure 800Pa Line conveying height 1100±50mm 1100±50mm 1100±50mm Ink uniformity test method : test on 625*726mm bare copper plate . After drying, use the 9 -point method of the ink tester to measure ( dry film thickness 30 ~40μm ); calculation formula : 100%- ( maximum value - minimum value ) / (2 * Average ) *100% .

Product Features

1. High yield: Using a mixed air spray gun to increase ink output,the production line speed is 3.0-4.5m/min ,and the output is increased by 30% compares to low-pressure spraying.

2. Ink Efficient: Adopting precise adjustable spacing technology to reduce the ink spray area between circuit boards;Ultra hig acceleration design,shorter spray distance compared to low-pressure spray machines,reduces ink waste by 30%,and lowers raw material costs.

3. Less exhaust gas: Using high viscosity ink,reducing the amount of ink diluent,reducing VOCs emissions for waste gas tratment.

4. Thick copper plate: Adopting a high viscosity oil supply system,the viscosity is increased by three times compared to low-pressure spraying machines,There is more hanging oil at the corners of the line.The 3oz thick copper plate can be sprayed in one go,reducing drying times,increasing production,and saving energy.

Key words:

PCB

Pcb solder mask ink spraying line

PCB spraying machine

Pcb ink spraying machine

Car parts coating robot

Solder mask ink coating equipment

Solder mask ink spray production line

Pcb ink spray equipment

Contact Us

Note: Please leave your email address, our professional staff will contact you as soon as possible!

Related Products

language

language